Wired glasses were the first successful attempt by the glass industry to bring a safety product to the market.

The idea is very simple and was based on that of the construction of the well-known "reinforced concrete". Concrete as a material is very different from glass, but it has a great resemblance! While it is a very resistant material to compressive forces, it is extremely sensitive to tensile forces. The same thing happens with glass.

So since in the cement industry the solution to the problem was found by inserting iron bars (or mesh) into the cement when it is still in liquid form, the exact same solution was adopted in the glass industry.

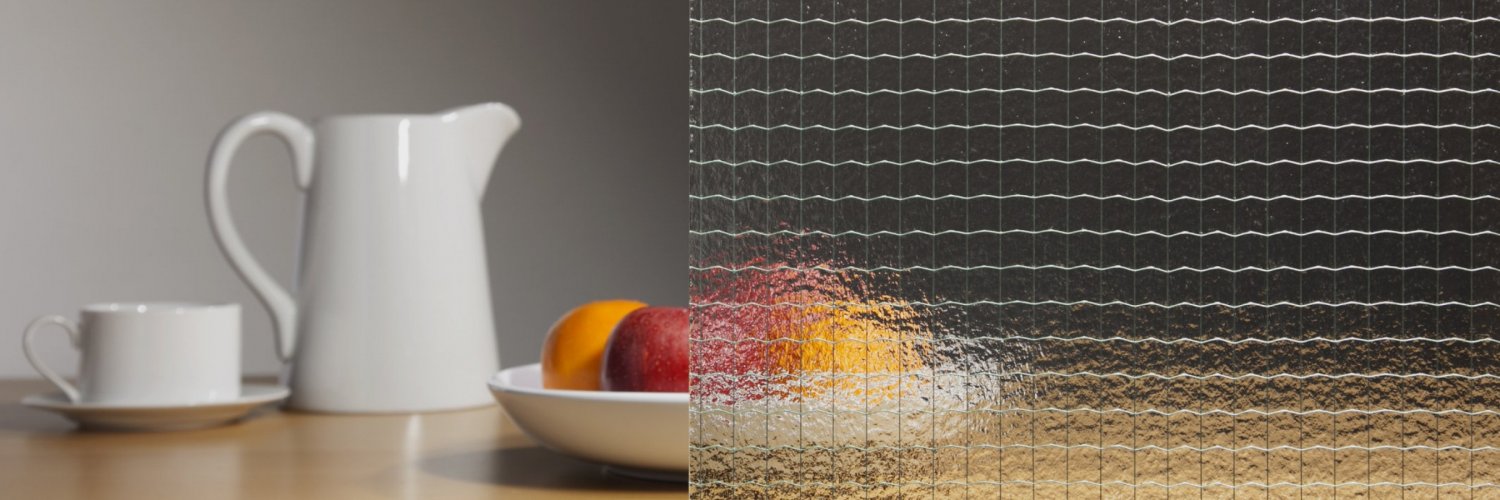

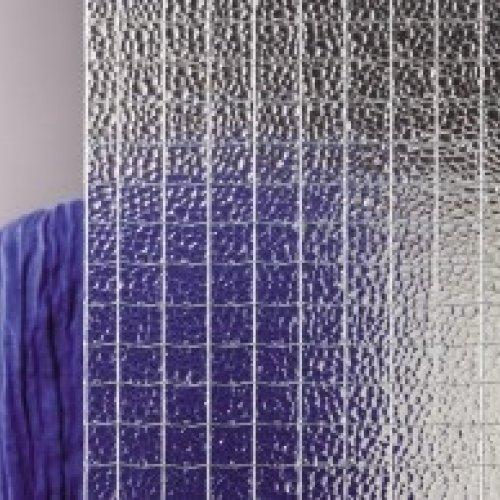

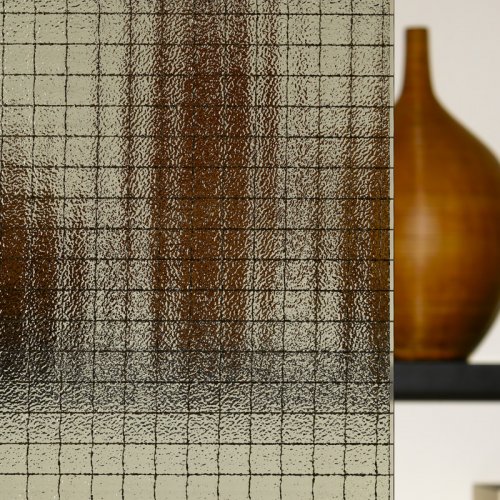

Thus was born the idea of wired glass. Its construction in terms of composition and melting is exactly the same as that of ordinary glass. The differentiation is at the stage where the glass is still in liquid form and enters the setting phase. At that time, a stainless steel wire mesh is inserted into the liquid mixture, which after cooling the glass remains trapped in its mass.

PROPERTIES

Reinforced windows, due to the metal mesh they carry in their mass have some additional properties compared to plain windows.

- They have greater mechanical strength in terms of tensile and therefore show increased elasticity.

- In case of breakage, the wire mesh holds the broken pieces, thus avoiding the undesirable consequences of an accidental breakage.

- Due to the metal mesh as well, these windows are an easy solution to the problem of fire safety, as they hold the flames even after they explode, giving the staff time to escape.

- Usually on the surface of the glass there are imprinted various decorative designs, which have a decorative use.

| Colour | Thickness | Size |

|---|---|---|

| Nashiji Clear | 06mm |

160,0 x 200,0 183,0 x 244,0 200,0 x 250,0 |

| Nashiji Bronze | 06mm |

122,0 x 250,0 187,5 x 250,0 |

| Nashiji Grey | 06mm | 122,0 x 250,0 |

CHARACTERISTICS

The physical characteristics are almost the same as those of the corresponding common glass. This is exactly how the factors remain, such as:

U: Thermal permeability coefficient

E: Emission factor

EA: Energy absorption coefficient

LR: Light reflection coefficient

UV: Ultraviolet permeability coefficient

Rw: Sound impairment factor

S: Selectivity coefficient

The following 2 factores are slightly reduced, due to the presence of the metal mesh:

SC: Total energy permeability coefficient

LT: Light transmittance

Due to the special properties of wired glasses, they have become very popular in a number of applications, but most of which nowadays have been "replaced" by more modern security products such as triplex and securit. However, because for many decades reinforced glass was the only glass safety product even today we see it in many applications such as:

- Balconies

- Shelters

- Terraces

- Skylights

- Elevator doors

- Doors of public buildings (barracks, schools, police stations, etc.)

- High glazing with no balconies (warehouses, industrial premises, etc.)