In 1903, a French chemist completely by random broke a bottle of cellulose acetate in his laboratory. He immediately noticed that during solidification the cellulose restrained the fragments of the broken glass. Thus the idea of welded laminated glass panes was born. I is also known as the 'triplex'. In 1910, Saint Gobain patented the production method. Further the technology was developed by Dupont, which, after the Second World War, produced for the first time triplex glass for cars.

Over the years, the cellulose because it was turning yellow, was gradually replaced by the Polyvinyl butyral (PVB) which until today is the predominant adhesive.

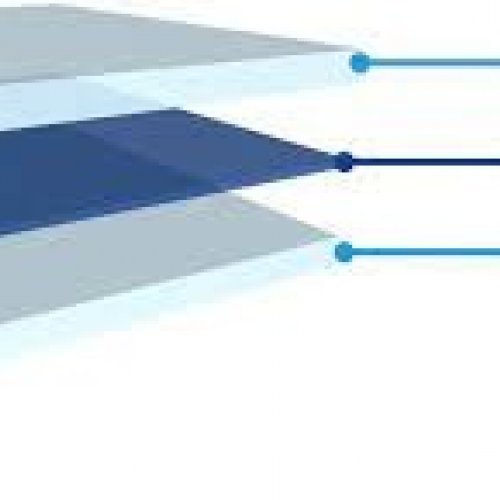

Today, triplex glass is a laminated safety glass manufactured in accordance with standard EN 12543. It consists of two or more glasses panes glued together by one or more interlayer membranes polyvinyl butyral (PVB).

After placing the PVB between the glass sheets, there are all together subjected to heat and pressure in an autoclave. It results in firmly adhering laminated PVB with the glasses panes.

In case of breakage, the fragments remain stuck to the PVB film, thus avoiding potential injuries from accidentally falling glass fragments. In fully framed installed pieces of glass held together by the PVB, the glass pane still retains a residual strength until replaced.

It should be clear that, in contrast to what people think generally, the triplex has lower breaking strength than of a simple glass of the same thickness. In a nutshell, this means that the triplex glass will break more easily than a simple glass of the same thickness. The reason which makes it an attractive option is not its resistance to fracture but his behavior after overcoming the limits of endurance. The fact is that once it breaks:

- it will not collapse uncontrollably to injured anyone.

- it will remain in place guarding the place (home, showcase, car, plane, etc.) until being replaced.

The thickness and number of glasses can be changed in order to create TRIPLEX glass with different characteristics thus complying with the security requirements of each type of application.

All types of glass can be incorporated into embodiments for making TRIPLEX. For example, a triplex glazing may be comprised of common white glass or pyrolytic coating or soft coating or colored glass. The use of extra-white glass for making a TRIPLEX composition provides high levels of transparency and excellent optical penetration without sacrificing any of the security features. This is especially necessary in applications requiring thick and solid construction as bulletproof, floors, glass aquariums etc.

The PVB film may be either transparent or translucent, or certain colored applications. In indoor applications, it is also possible to combine them for decorative effect.

In the international nomenclature, it has come to name each pane triplex with a XXX.YY form of code where the successive "X" represent the thicknesses of glass panes and Y represent the number of PVB film (thickness 0,38mm each) which are inserted into each intermediate soldering.

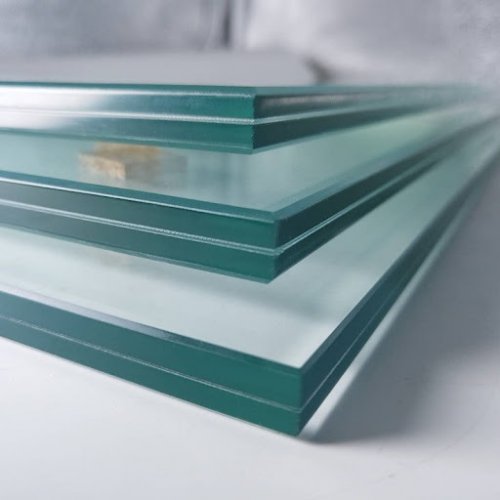

For example, the TRIPLEX 33.1 consists of two glass sheets of 3mm each, and a 0.38 mm PVB film.

Correspondingly, the glass pane 8108.28 is a triplex consisting of a glass pane 8mm, 2 membranes 0,38mm, one pane 10mm, 8 membranes of 0,38mm and finally another glass thickness 8mm.

Advantages

The rapid expansion in the use of triplex glass is not random. It is due to a number of advantages in different areas, the use of this kind of glass pane with respect to the public.

Safety

On the security aspect, the triplex glass offers excellent "passive" safety in comparison to common glass. By "passive" we mean that the triplex glass, contrary to what is mistakenly believed, breaks as (if not more) easily as common pane. Its safety features are due to its behavior after overcoming breaking. The fragments resulting from the crushing stay firmly attached to the PVB film. Thereby they are rendered harmless and are unable to cause serious injury. This unique feature is what makes the triplex glazing prescribed as first class safety glass.

Protection

Triplex glass offers increased protection to property and to people providing a barrier between the inside and the outside, even after it is broken. Although it will break (relatively easily) if hit with a hammer, stone or something else, the intermediate PVB film will prevent penetration by ensuring that any attempt of violent breach will be slow and noisy. The level of resistance to invasion depends on the categorization of each pane (the more the mass of the glass and the more the contained film, the higher the safety class of the pane).

Moreover, if the glass is mounted on a fixed frame, after crushing and it remains in place, even if broken. This giving time for the person to replace the glass whenever he wants without leaving exposed his property (home, shop, car, etc.). Finally, the stay of the pane in place ensures that properties (goods, furniture etc.) are protected against from damage, accidental collapse and theft or weather.

Sound Insulation

Triplex glass exhibits excellent sound insulation capabilities due to the adhesive PVB membrane. Being inherently flexible, it has the ability to damp the resonance phenomena, and eliminates the "acoustic window" in the medium and high frequencies (1000-2.000 Hz). So in many cases the use of triplex glazing offers an excellent and inexpensive solution to the problem of sound insulation. It helps eliminates more systematic annoying noises, such as cars traffic, airplanes and trains. It contains extremely important sound energy amounts in this frequency range.

Limitation of Ultraviolet radiations

An additional property of the intermediate PVB film, is that it shows a very high retention of harmful ultraviolet radiation.

This property makes the triplex glazing an excellent antidote to the disturbing phenomenon of colors fading (goods, furniture, carpet, flooring, etc.). Furthermore, no one should underestimate the beneficial effect of protecting the skin from sunburn or just tan.

Properties

The TRIPLEX glazing offer enhanced safety in case of breaking, with the fragments remain in place due to the intermediate PVB film or (EVA) and thus minimize the risk of injury.

Moreover, unlike some plastic safety film that stick retrospectively onto already installed, a Triplex glass remains in place in case of breakage thus protecting the interior of houses, shops, etc. in which it is placed.

It is also important to note that the TRIPLEX glass absorbs sound vibrations in a wide range of frequencies, thereby providing much better sound insulation than an ordinary glass of the same thickness.

Finally, it should not be underestimated that the TRIPLEX glazing provides high levels of protection from ultraviolet (UV) radiation. So it has surprisingly good results to help protecting against fading caused by the sun by eliminating up to 99% of UV radiation. This is advantageous in applications such as shop fronts and windows.

The TRIPLEX and tempered TRIPLEX are extremely long-lasting and stable to UV radiation, even in prolonged direct exposure to sunlight.

The various visual and energy efficiency coefficients for permeability, reflection and absorption depend on the type of glass and the color of PVB films.

The behavior of PVB films in TRIPLEX (or tempered TRIPLEX glasses) varies depending on the temperature at which they are submitted. With such compositions, triplex glass is mechanically stable at temperatures of from -10ºC to + 45ºC. The thermal transmittance is similar to that of monolithic glass of the same thickness. For example, the U-value of tempered TRIPLEX 33.2 or 6.8mm glass is 5.7 W / (m² ºK). Furthermore, it can greatly enhanced thermal insulation levels, if used in the production of TRIPLEX energy panes.

The applications are varied. Generally, it can be categorized based on consumer needs which can be covered.

Examples can be mentioned as general categories of applications such as the following:

- Awnings, patios and glazing at elevated heights

- Schools, gyms, swimming pools, hospitals and general public spaces with important mobility of people.

- Curtain Walls

- Storefronts

- Showcases artworks

- Aquarium, zoos

- Hotels

- Houses in noisy environments

- Prisons, embassies, banks and security personnel vehicles

- Police buildings

- Parapets, balustrades

- Showers

- Automotive industry

- Decoration

Naturally applications are not limited to those mentioned above, but also in any other application or needs in any the technical features of the glazing family products.